Wraps are not created equal

- June 29th, 2010

- Write comment

Installations is a very important step in completing successful wrap project. Most of the wrap companies provide professional installation service which includes certain undisclosed number of steps, to ensure your satisfaction. However there is a lot of details that could greatly influence the cost of the wrap and it final outcome. By default on commercial applications, door handles are not removed and the vinyl is simply cut and tucked under them. In most cases this practice is perfectly fine and overall look of the graphics is not compromised.

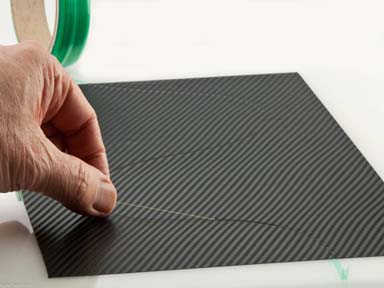

In certain cases like when using solid colour vinyl or specialty vinyls like 3M Carbon Fibre, it would be recommended to spend additional time and remove as much as possible to ensure seamless installation. Vinyl can be tucked in properly when the lights are off the car, and there is no issues with slight vinyl shrinkage due to temperature changes.

*minimum purchase $200. Retail only.

*minimum purchase $200. Retail only.